The Technology

What is a high temperature heat pump and how does it work?

A high temperature heat pump (HTHP) essentially works by using the same principles as a normal heat pump: transferring thermal energy from one space to another. Heat is taken from a low temperature heat source by cooling it down. The temperature of the heat is increased inside the heat pump. This now higher temperature heat is transferred to a high temperature heat sink by heating it up. A HTHP differs from normal heat pumps in that it can produce temperatures that are above what are generally required for domestic use.

One of the many benefits of using a heat pump is the level of energy efficiency it can provide. Heat pump efficiency is measured by its Coefficient of Performance (CoP). For every unit of electricity used, a heat pump has the potential to produce several times the units of heat. The higher the units of heat produced in proportion to electricity used, the higher the CoP. Another advantage is that a heat pump can provide cooling in addition to heating, allowing for additional savings where energy costs are concerned.

Ultimately, a HTHP can prove an invaluable tool for industrial players who demand higher processing temperatures. HTHPs provide the opportunity to reduce carbon emissions, as they do not rely on fossil fuels to operate. In addition to this, they can offer the possibility of reduced expenses when considering the ever-rising costs of fossil fuel-based energy sources. A HTHP will in fact allow cost savings compared to electric boilers too, as part of the electricity for steam production is replaced by waste heat energy sources in a HTHP.

The HighLift technology

The HighLift heat pump technology is based on the Stirling cycle- an invention that goes back more than 200 years. The Stirling cycle is a thermodynamic cycle where working gas is cyclically compressed and expanded at different temperatures. This results in a conversion of heat energy to mechanical work. The HighLift uses a reverse Stirling cycle, so the heat pump adds mechanical work (through an electric motor) to increase output temperatures.

Our heat pump uses less than 2kg of Helium as its working medium. Helium is non-toxic and possesses many environmentally friendly attributes, such as being non-flammable, with a GWP (global warming potential) and ODP (Ozone depletion potential) of zero. The use of this gas therefore renders the heat pump suitable for any application.

Our HighLift heat pumps have a rated output of 750 kW heat. The HighLift is designed for heat pumping applications with sink temperatures of up to 200°C. As the working medium of the process is a gas and does not undergo any phase changes during the process, the HighLift heat pumps have very few restrictions on source and sink temperatures. Also, the process will quickly find a new equilibrium state with changing temperatures, meaning that the process is very robust with respect to large and sudden changes in inlet temperatures.

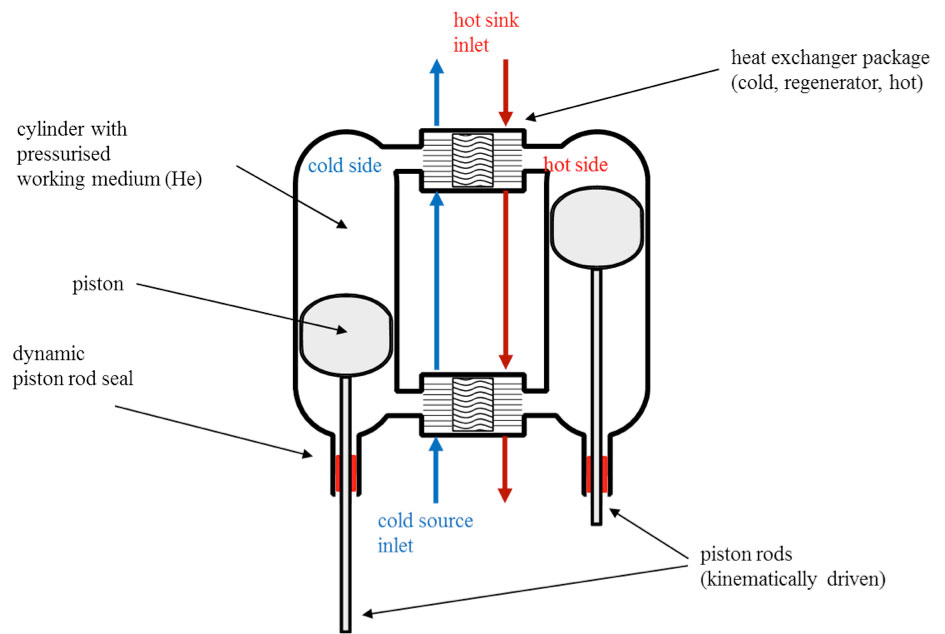

Many aspects of the design resemble those of large ship diesel engines. The heat pump consists of a four-cylinder double-acting engine with four gas circuits, a normal crankcase with crankshaft, oil lubricated bearings and crossheads, connected by two-piece connecting rods. The figure below shows a schematic overview of the heat pump.

Schematic overview of the heat pump configuration.

Two pistons move phase shifted to each other (with respect to the crank angle). The two pistons work together to move the gas from one side of the heat pump to the other, and to compress and expand the gas. When most of the gas is in the hot side of the heat pump, the pistons compress the gas and when most of the gas is in the cold side, the pistons expand the gas.

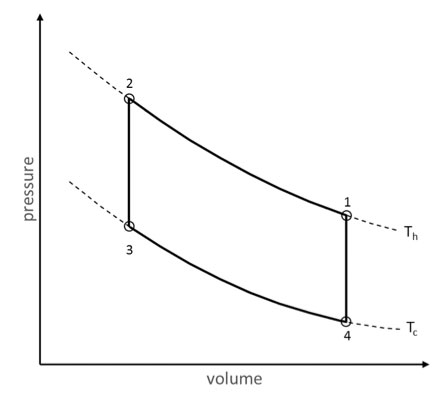

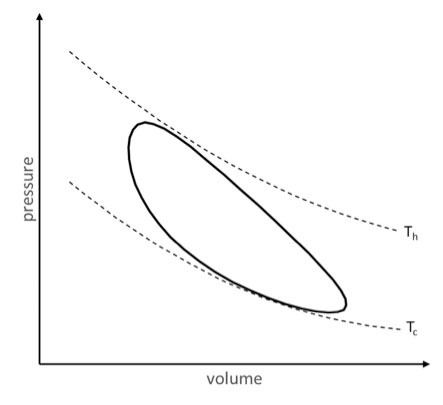

During one revolution, the working medium undergoes state changes that approximates the ideal Stirling cycle. The figures below shows a comparison between the ideal and real Stirling cycles.

The ideal Stirling cycle (a) compared to the real heat pump cycle (b) in p-v diagrams. The real cycle is based on a simulation model of the heat pump with parameters matching the actual parameters of one of the installed heat pumps.

(a) Ideal Stirling cycle in a p-v diagram. State 1-2 isothermal compression, state 2-3 constant volume cooling, state 3-4 isothermal expansion and 4-2 constant volume heating.

(b) Real Stirling cycle based heat pump cycle in a p-v diagram. The motion of the reciprocating pistons approximates the ideal state changes of the working medium.