About us

The HighLift’s technology was developed in Norway in the mid 2000s, from R&D initiatives based on Stirling cycle technology. Olvondo Technology was established in 2016. The ownership was later re-structured when LOS Gruppen and Westcon became joint owners in a 50/50 partnership. Our HighLift heat pumps are manufactured at Westcon’s facilities in Bømlo, western Norway.

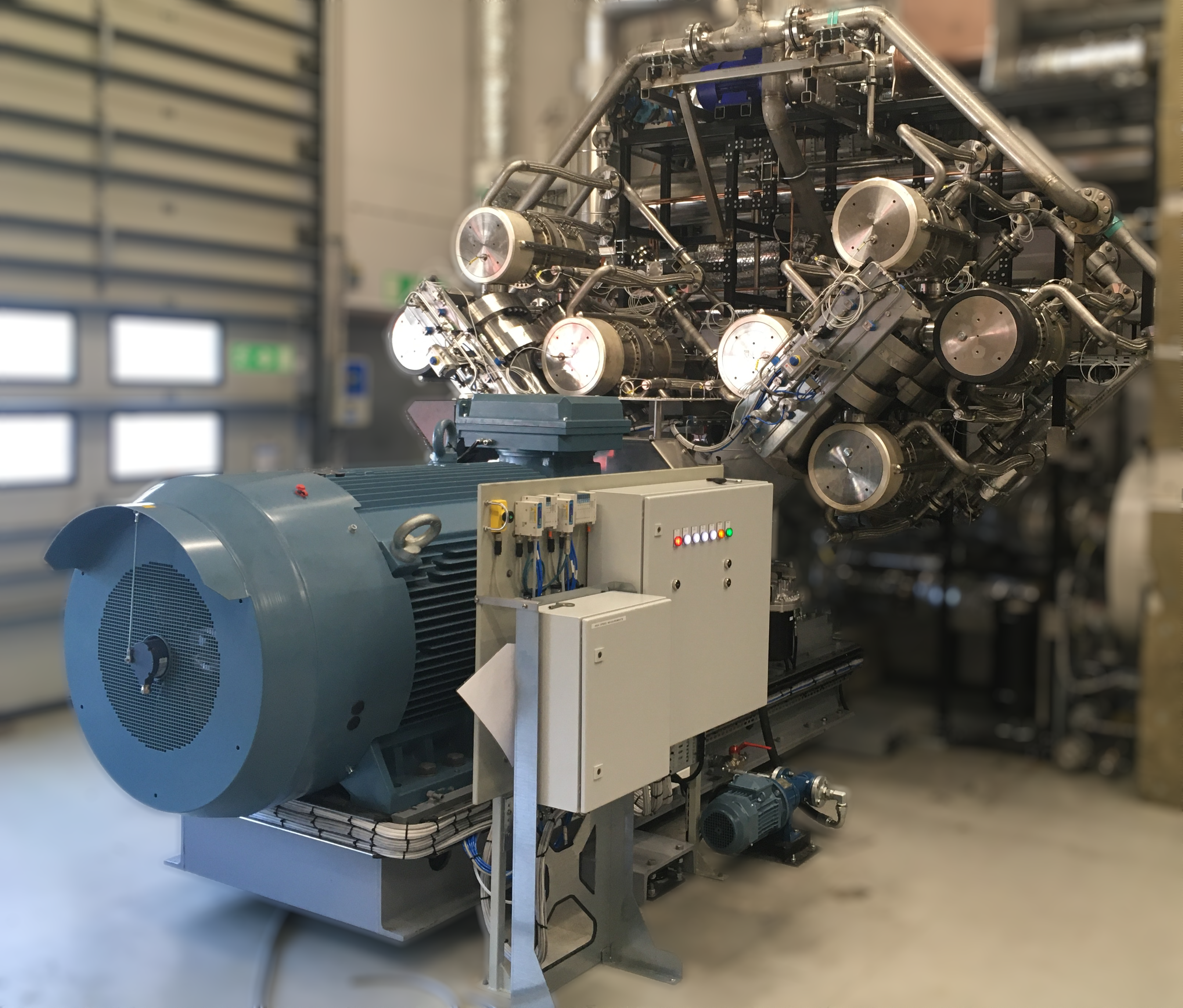

The HighLift heat pump is based on the legacy of a technology so useful it’s been utilised for more than 200 years- the Stirling cycle. Olvondo Technology has developed its innovative high temperature heat pump around this principle, which is essentially based on the concept of compression and expansion of a working gas at different temperatures. This leads to a conversion of heat energy to mechanical work. Our heat pump uses a reverse Stirling cycle, so the heat pump adds mechanical work (through an electric motor) to increase output temperatures.

What’s unique about the HighLift technology is its ability to provide much higher temperature lifts compared to other industrial heat pumps, thus capable of delivering steam with temperatures of up to 200°C. Also, our heat pump uses helium as a working medium, which is non-toxic, non-flammable, has a GWP (Global warming potential) and ODP (Ozone depletion potential) of 0.

Typical customers of this technology are industrial players within food, aquaculture, chemical, pharmaceuticals and others with high demand for steam. A growing number of industries are taking it upon themselves to embrace greener forms of energy, and the HighLift facilitates their efforts.

With well over 50,000 operational hours from commercial services, HighLift is unique as the world’s first industrial Very High Temperature Heat Pump (VHTHP) based on a reverse Stirling process. Olvondo Technology and its owners are actively pursuing opportunities within renewable energy as a fundamental part of the company’s development. All share a common interest in becoming manufacturers of Green Shift technologies. We’ve harnessed the simple brilliance of a centuries-old technology and transformed it to create a ground-breaking innovation. The resulting benefits are two-fold: increased cost savings and a significantly reduced carbon footprint.